Big 6 Gearbox Rebuild - Case Study

At the first test drive it became clear that the newly restored six kept jumping out of gear and that the gearbox would have to come out and be repaired. As it happens my friend Roger Williams had just sent out an invitation to subscribe to one of ten new crown-wheels and pinion sets he was about to manufacture. The new set would have the added advantage that the original ratio of the crown-wheel an pinion would be increased to (9x31), giving a higher top speed of about 15 mph, a better range through all the gears and improved economy.

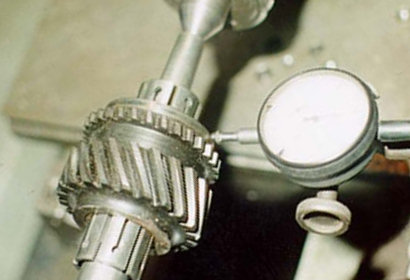

The gearbox was dismantled in Roger's workshop and after a thorough cleaning put on a special mount, which would make working on it that much simpler. Roger had done his homework and found replacement parts for all the bearings. New bushes and synchromesh were manufactured 'on the spot' on Roger's impressive arsenal of industrial machinery, such as lathe, miller, surface and cylindrical grinders.

The new crown-wheel and pinion was looking impressive in it's grease paper wrapping, manufactured to Roger's specification on a CNC lathe of one of his suppliers.

Also a special set of jigs and tools was manufactured to enable Roger to do the job with a minimum of fuss and without damaging any of the original components.

Spending a day in Roger's workshop soon re-enforces the impression that a passion for quality is paramount in his work. An impressive array of bore gauges and micrometers was used to check everything to the finest tolerances. If something like the end float of a gear on the pinion shaft, was not quite right, it was soon corrected by putting one of the thrust washers back in the surface grinder to take it to the required specifications.

Also a special new diaphragm clutch was installed replacing the old fashioned three fingered one. The carbon thrust bearing was replaced by a sealed release bearing in a new housing. A sprung clutch plate was used. This enabled me to mount the new C/V drive shafts without the heavy bibax joint.

The Six now cruises nicely at 80 mph (only on German motorways of course!).

Written by Marcus Lasance

Contact Mr. Williams at Steam-Car-Developments for assistance with updating the mechanical features of your Traction series vehicle.